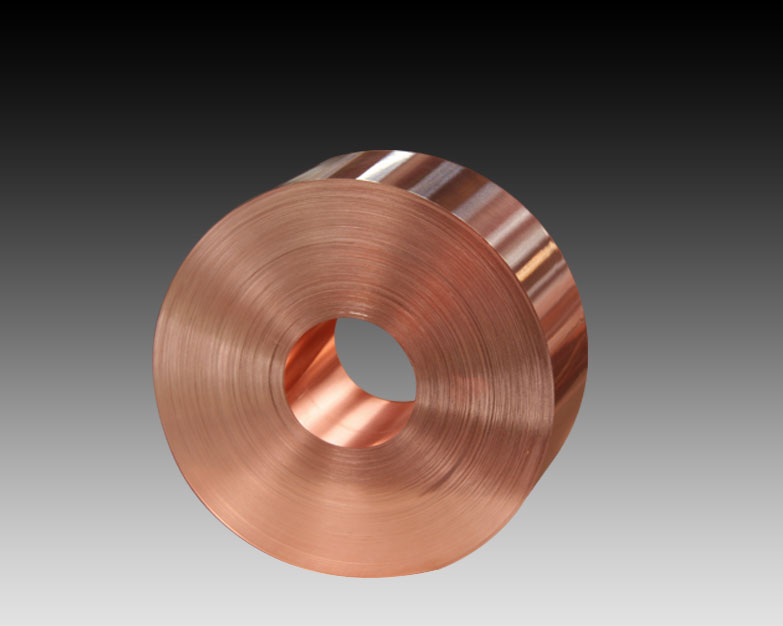

Copper foil tape is divided into single-sided adhesive coating and double-sided adhesive coating. Single-sided coated copper foil tape is divided into single-conductor copper foil tape and double-conductor copper foil tape. Single-conductor copper foil tape means that the coated surface is not conductive, and only the other side of copper is conductive. ; Double-conducting copper foil tape means that the rubber-coated surface is conductive, and the copper on the other side is also conductive, so it is called double-conducting that is double-sided conductive. There are also double-sided adhesive-coated copper foil tapes that are processed with other materials into more expensive composite materials. The double-sided adhesive-coated copper foil has two types of adhesive surfaces: conductive and non-conductive. Customers can according to their own needs for conductivity To choose.

When storing the goods, please keep the room dry and ventilated. The domestic copper is generally stored for 6 months, while the importing country can store it for a longer time and is not easy to oxidize. Products are mainly used to eliminate electromagnetic interference EMI and isolate the harm of electromagnetic waves to the human body. They are mainly used in manufacturers of computer peripheral wires, computer monitors and transformers.

PCB copper thickness is generally divided into 1OZ (35um), 2OZ (70um), 3OZ (105um), of course there are thicker bai, the copper thickness depends on what kind of board you make du, like zhi switching power supply with high current dao2OZ, 1OZ of general signal is enough. Generally, the double-sided board is 1oz. The inner layer of the multilayer board is generally 1/2oz 1/3oz, and the outer layer is 1oz 1/2oz 1/3oz. The copper thickness of the power board is high. Many foreign countries require 2oz 3oz and even higher.

In order to ensure the system temperature and reduce the impact of copper foil impedance on the system power consumption, take the copper foil thickness of 1oZ as an example, it is recommended to specify a 1mm line width to carry a current of 1A. When the trace width is not enough and the current is relatively large, you can Using bare copper to increase the thickness of the trace can increase the current capacity.

The current strength of the signal. When the average current of the signal is large, the current that the wiring width can carry should be considered. The line width can refer to the following data: The thickness of the copper foil in the PCB design, the relationship between the wiring width and the current, different thicknesses.