According to the occasion, copper strips are generally rarely selected, and galvanized flat steels are mostly used for connection by welding.

When welding, pay attention to the following issues: The connection of the grounding body should be firm and reliable, and overlap welding should be used. When the grounding body is made of flat steel, its lap length is twice the width of the flat steel, and there are three adjacent sides to be welded; Round steel, the lap length is 6 times the diameter of the round steel, and welding is applied on both sides. After the grounding body is connected, the grounding resistance should be tested, and the grounding resistance should meet the requirements of the specifications.

The grounding trunk line usually uses flat steel, round steel, copper rod, etc. The indoor grounding trunk line is mostly open, generally laid in an electric well or cable trench. The grounding trunk line can also use the existing steel pipe, metal frame, and metal frame in the building, but the grounding jumper should be made at the connection of the steel pipe, metal frame, and metal frame.

The grounding trunk line is connected by lap welding, and the requirements for lap welding: the overlap between flat steel (copper bars) is twice the width of the flat steel (copper bars), and welding is not less than three sides; round steel (copper rod) ) The overlap between round steel (copper rod) is 6 times the diameter of round steel (copper rod), double-sided welding; the overlap between round steel (copper rod) and flat steel (copper bar) is 6 times the diameter of round steel (copper rod), Double-sided welding; between flat steel (copper bar) and steel pipe (copper pipe), close to the surface of 3/4 of the outer diameter of the pipe, and weld on the upper and lower sides. Flat steel and angle steel are welded, close to the outer sides of the angle steel, and the upper and lower sides are welded. The welding seam should be full and have sufficient mechanical strength. There should be no defects such as slag inclusion, meat biting, cracks, virtual welding, pores, etc., after the coating of the welding place is removed, anti-corrosion treatment should be done.

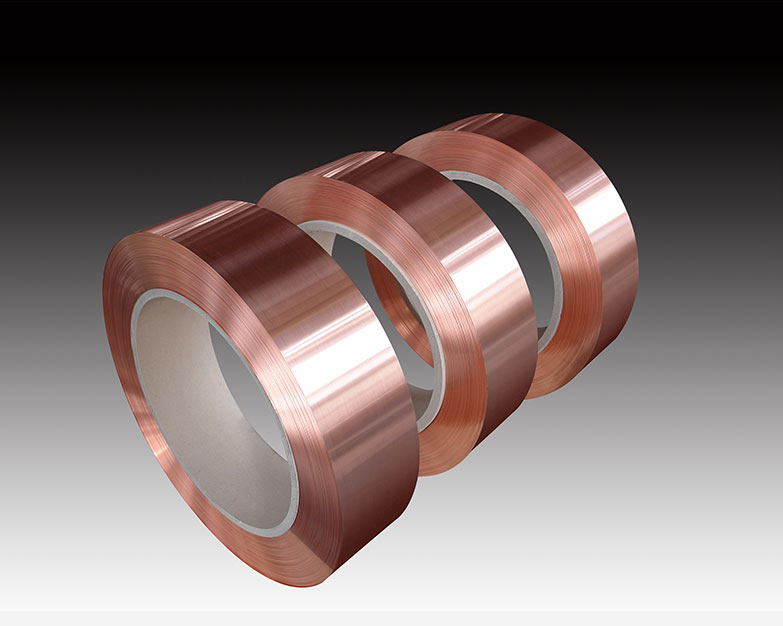

What is the difference between electrolytic copper and rolled copper?

1. Rolled copper has good flexibility, Chen Bengao

2. Electrolytic copper is not resistant to bending and has low cost

The cost of electrolytic copper is cheap and its flexibility is not good, so it cannot be used as an FPC that is often bent. The cost of rolled copper is higher and its flexibility is good.

The surface roughness of the copper strip is controlled by the roll roughness. Generally, the roll du is controlled at 0.2-0.4μm, and the surface RA of the copper strip after rolling will be somewhat lower.

The surface quality is very poor. It should be caused by defects such as surface peeling, delamination, pinholes, roll marks, and chromatic aberration. It has nothing to do with surface roughness.

The surface roughness of copper strip only affects the use of copper strip, such as electroplating, coating, etc.