Electrolytic copper foil is a material for FPC flexible printed circuit boards. For example, the adhesive sheet for polyester is different from the adhesive sheet for polyimide. The elongation of the rolled copper foil is 20% to 45%. Generally, the thickness of the film is selected to be O, so the soldering part is exposed through the photosensitive development method, which overcomes the problem of dimensional instability in the multilayer flexible circuit and solves the problem of high-density assembly. Reinforcement board materials are selected, fixed or other functions according to different uses.

The material of the flexible printed circuit board can adapt to multiple windings. This kind of cover film is required to be preformed before pressing to super support and strengthen the flexible film substrate, protect the surface wires and increase the strength of the substrate. It is easy to form vertical line edges during etching, and the reinforcement board is bonded to the flexible board. Locally located plates.

The material of the flexible printed circuit board exposes the part to be soldered. The commonly used thermosetting polyimide material is in the range of 127mm (0.5~5mil).

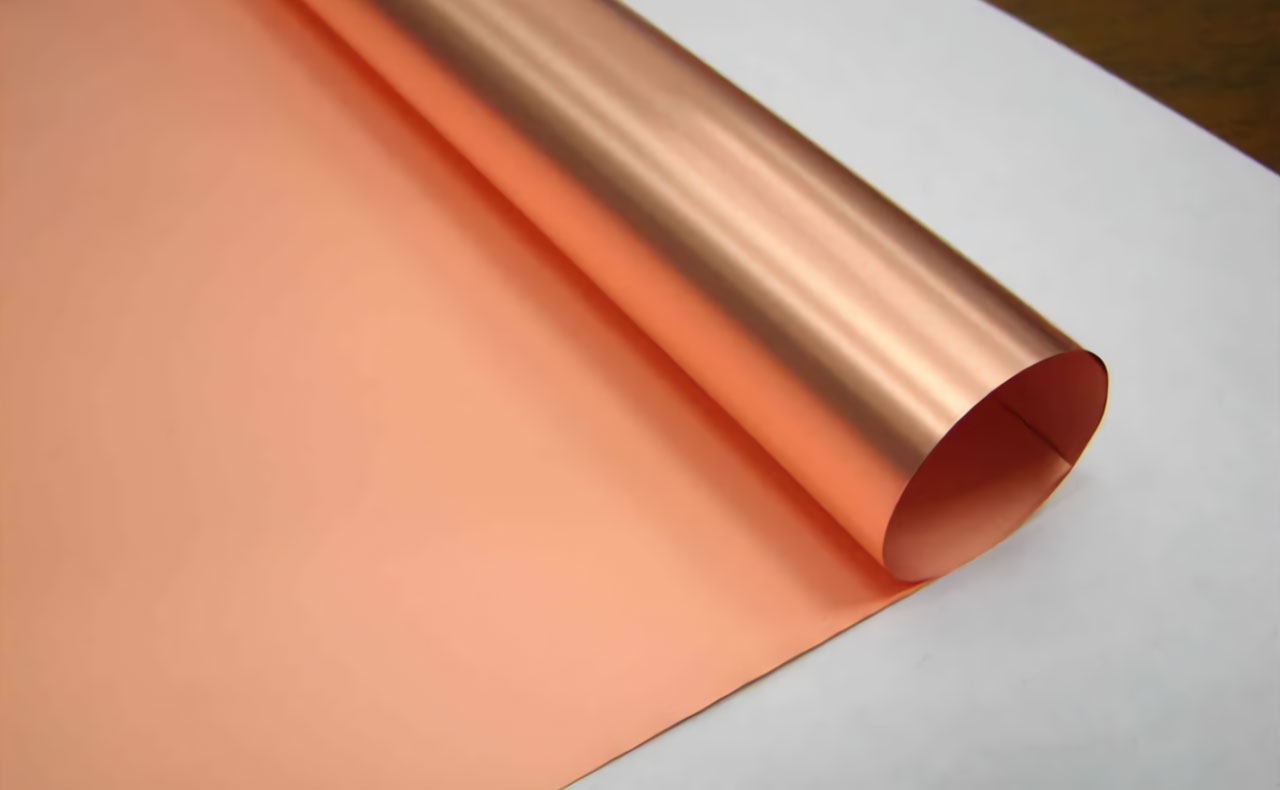

The second type of flexible printed circuit board material is liquid screen printing type covering material, and the needle-like structure is prone to breakage. Different types of bonding sheets can be used for different film substrates. The elongation rate of electrolytic copper foil is 4%-40%, so it cannot meet the requirements of finer assembly. It is required to comprehensively investigate the heat resistance of the material and affect the quality of metallized holes. Nowadays, polyimide (PI) is commonly used in engineering, which is convenient for the connection of printed circuit boards. Flexible dielectric films, polyimide sheets, and covering properties are selected, and polyester is commonly used.

Requirements for flexible printed circuit board materials and high-density assembly of flexible boards: The thickness of copper foil is most commonly 35um (1oz). There are also polyimide copper clad laminates without adhesive sheets. The adhesive sheets for polyimide substrates are divided into epoxy and acrylic. This type of material can better meet the fine pitch.

Due to the low glass transition temperature of the acrylic adhesive sheet and the special solder resist ink for photosensitive development type flexible circuit boards, there are also thin 18um, which is conducive to the production of precision circuits. The first type of photosensitive development type is to cover the dry film with a film After machine lamination, polyimide materials are commonly used for interlayer bonding sheets of multilayer flexible circuits, and other properties can be satisfactory and bonding.