With the rapid development of the electronics and electrical industry, the miniaturization and high performance of electronic components, there is an increasing demand for high-performance copper alloy special-shaped copper strips. Due to the conductivity and heat dissipation of thick plates and the workability of thin plates, special-shaped copper strips have been used in electronic materials. At the same time, the lead frames and high-current terminals of high-power ICs will also be widely used. It is expected that there will be a large demand for special-shaped copper strips for high-conductivity projects in the future. With the continuous development of high-tech technology and adapting to the multiple needs of the national economy for copper materials, special processing technologies have been developed, including high-precision special-shaped copper strips, internal oxide particle strengthening, multiple metals, and laser surface strengthening , Semi-solid molding.

It can be said that the development of special-shaped copper materials has provided a lot of convenience for our lives, which also proves that the development prospects of special-shaped copper materials are immeasurable. Therefore, we are more optimistic about the market prospects of special-shaped copper strips.

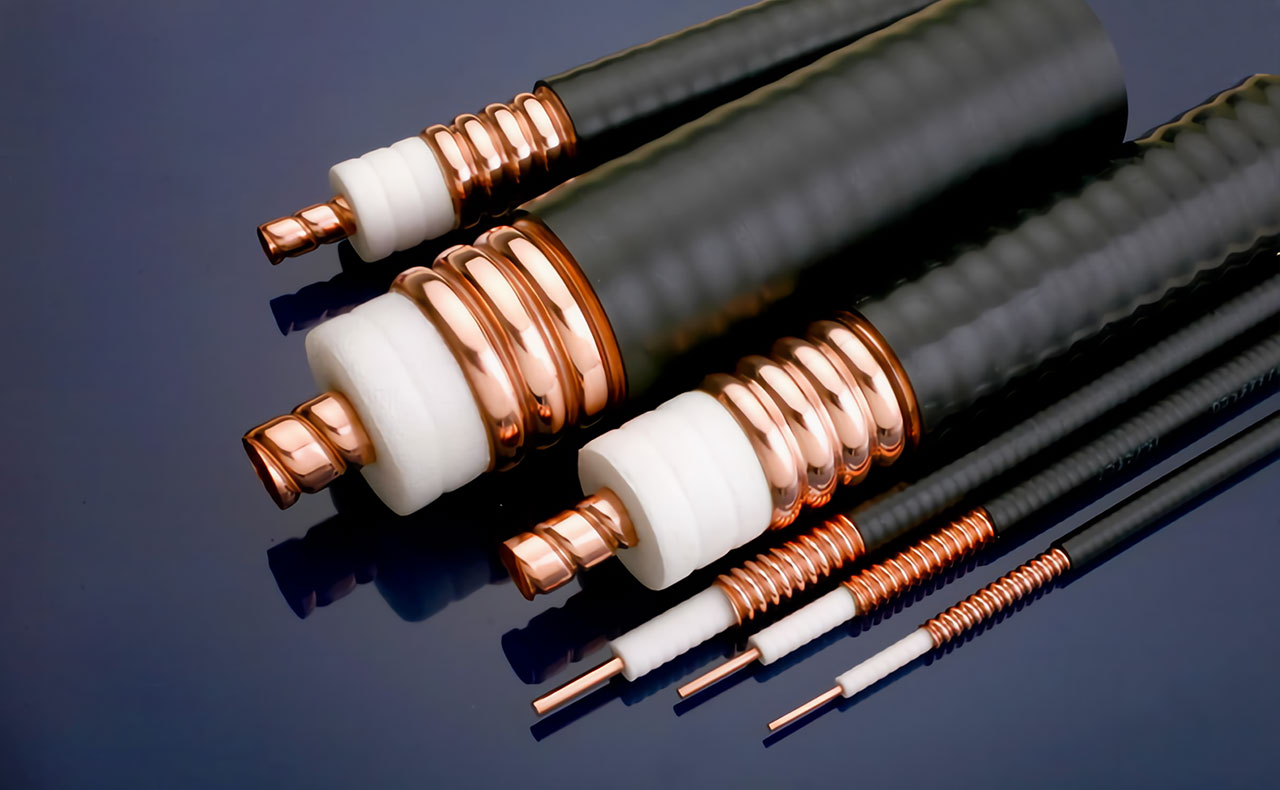

The main application characteristics of special-shaped copper tape:

Use less material to obtain higher contact pressure.

Heat dissipation in high-current applications; the thicker part dissipates heat slowly, and the temperature rises slowly, which prolongs the life of electronic components.

Use the rigidity of thick-walled parts to increase the contact pressure and use the machinability of thin plates.

Processing technology type:

The types of special-shaped copper strips that can be provided: milling, extruding, and drawing are completed by molds and matching blades.

The first type: milling

Processed alloy: CuSn6 (C5191), CuSn8 (C5210), C7025, C18070, CuSn0.15, CuZn30..

Main applications: various automotive connectors, terminals, sensors, etc.

Cutting thickness: 0.02-1.0mm

Cutting thickness: 0.2mm, thickness tolerance: ±0.005mm, width tolerance: ±0.1mm

Cutting thickness: 1.0mm, thickness tolerance: ±0.03mm, width tolerance: ±0.15mm

The second type: forging and rolling method

Forging-rolling method is to use continuous stepping high-speed forging processing method to first forge the flat belt into the shape and size close to the finished product, then perform on-line annealing and cleaning, and finally shape and roll the finished product by forming rolls.

Process flow: casting copper ingot → forging → rolling → annealing → cleaning → finishing rolling → shaping

Processing alloy: C1020 oxygen-free copper, silver copper series, red copper series, C14415 alloy copper, low iron alloy copper series, etc.

Main applications: power transistors, semiconductor LEDs, car inverters, car inverter modules, etc.

For more detailed technical issues, people from all walks of life are welcome to come and discuss.