Cable copper tape is an indispensable part of life now. In daily life, cable copper tape plays the protective role of grounding for us. So, what are the main applications of cable copper tape?

The copper tape of the cable plays the role of grounding protection to prevent the leakage of the high-voltage power cable from breakdown. When the internal breakdown of the high-voltage power cable occurs due to some reason, the high-voltage electricity will be absorbed by the copper strip and scattered by the ground wire. If the breakdown current is relatively large, the copper strip can also absorb large current. When the current is too large, the high-voltage drop type The protection switch will act to protect the safety of the person and equipment.

The cable is usually a rope-like cable formed by several or several sets of conductors each twisted at least two. Each set of conductors is insulated from each other and is often twisted around a center. The entire outer surface is highly insulated Overlay.

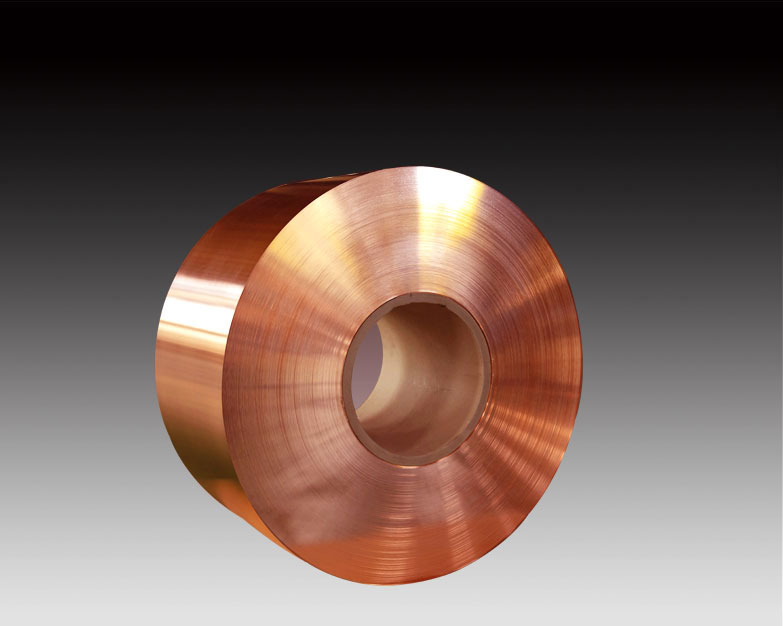

Copper tape is a metal component, mainly used in the production of electrical components, lamp caps, battery caps, buttons, seals, connectors, mainly used as electrical, thermal, and corrosion-resistant equipment. Such as electrical components, switches, gaskets, gaskets, electric vacuum devices, radiators, conductive base materials and automobile water tanks, heat sinks, cylinder plates and other parts.

What measures can the cable factory take to reduce the chance of copper strip conductor oxidation?

Almost all cable factories are faced with the problem of oxidation of copper tape conductors. In terms of the chemical characteristics of metallic copper, it is necessary to maintain the reducing properties of metallic copper. In daily production, the following measures can be used to reduce the probability of copper strip conductor oxidation:

(1) Select high-quality metal copper rods, standardize supplier transportation and delivery processes and systems. After the copper rods arrive at the company, take transparent plastic film sealing measures, and after copper conductors are drawn and stranded, transparent plastic film sealing measures should be taken ;

(2) Adopt a suitable copper wire drawing process, regularly check the annealed parts of the wire drawing machine, preferentially select the drawing oil containing antioxidants, check the emulsion concentration regularly, and replace it before the expiration date;

(3) The passivation treatment technology is adopted for the copper wire stranding and extruding insulation process;

(4) Establish quality awareness and strengthen business training to make operators of the above processes aware of the adverse consequences of copper wire oxidation.