Copper foil is actually a negative electrolytic material. Copper foil is a thin, continuous metal foil deposited on the base layer of the circuit board. As a conductor of PCB, copper foil is easy to adhere to the insulating layer, accept the printed protective layer, and form circuit patterns after corrosion. Copper foil has low surface oxygen characteristics, can be attached to a variety of different substrates, such as metals, insulating materials, etc., with a wide temperature range. Mainly used in electromagnetic shielding and anti-static, the conductive copper foil is placed on the substrate surface, combined with the metal substrate, which has excellent conductivity and provides the effect of electromagnetic shielding.

The copper foil is classified according to different ways as follows

1. According to the thickness, it can be divided into thick copper foil (greater than 70μm), regular thickness copper foil (greater than 18μm and less than 70μm), thin copper foil (greater than 12μm and less than 18μm), ultra-thin copper foil (less than 12μm)

2. According to the surface condition, it can be divided into single-sided processing copper foil (single-sided hair), double-sided processing copper foil (double-sided rough), smooth-faced copper foil (double-sided hair), double-sided light copper foil (double-light) And very low profile copper foil (VLP copper foil) copper foil, etc .;

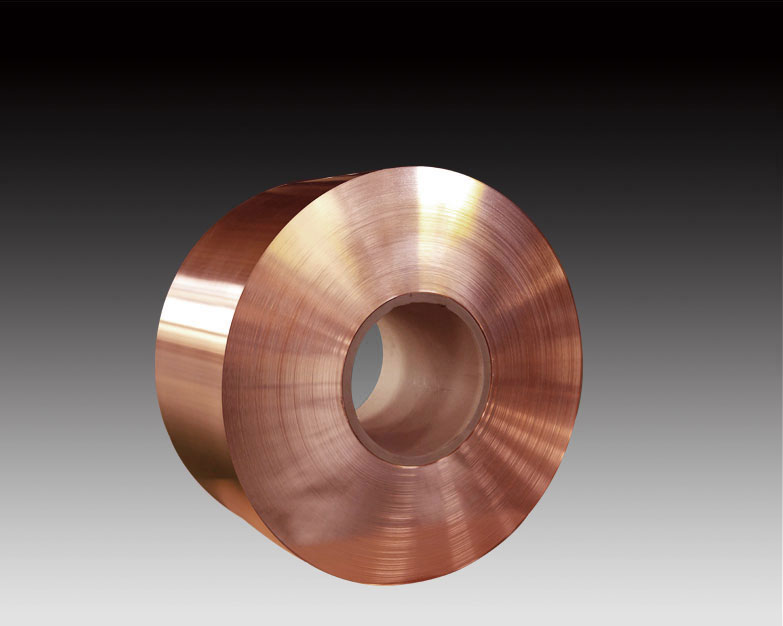

3. According to the production method, it can be divided into electrolytic copper foil, rolled copper foil and covered copper.

4. According to the scope of application, it can be divided into:

Copper-clad laminate (CCL) and copper foil for printed circuit boards (PCB): CCL and PCB are the most widely used fields of copper foil. PCB has now become an indispensable main component for most electronic products to achieve circuit interconnection. Copper foil has now become a key material for PCBs that play a supporting and interconnecting role in electronic products. At present, the vast majority of applications in the CCL and PCB industries are electrolytic copper foils;

Copper foil for lithium ion secondary batteries: According to the working principle and structural design of lithium ion batteries, anode materials such as graphite and petroleum coke need to be coated on the conductive current collector. Copper strip for calendering copper foil has become the first choice for negative electrode current collectors of lithium ion batteries due to its characteristics of good conductivity, soft texture, mature manufacturing technology, and relatively low price.

Electromagnetic shielding copper foil: mainly used in hospitals, communications, military and other fields that require electromagnetic shielding. Due to the width limitation of rolled copper foil, electromagnetic shielding copper foil is mostly electrolytic copper foil.