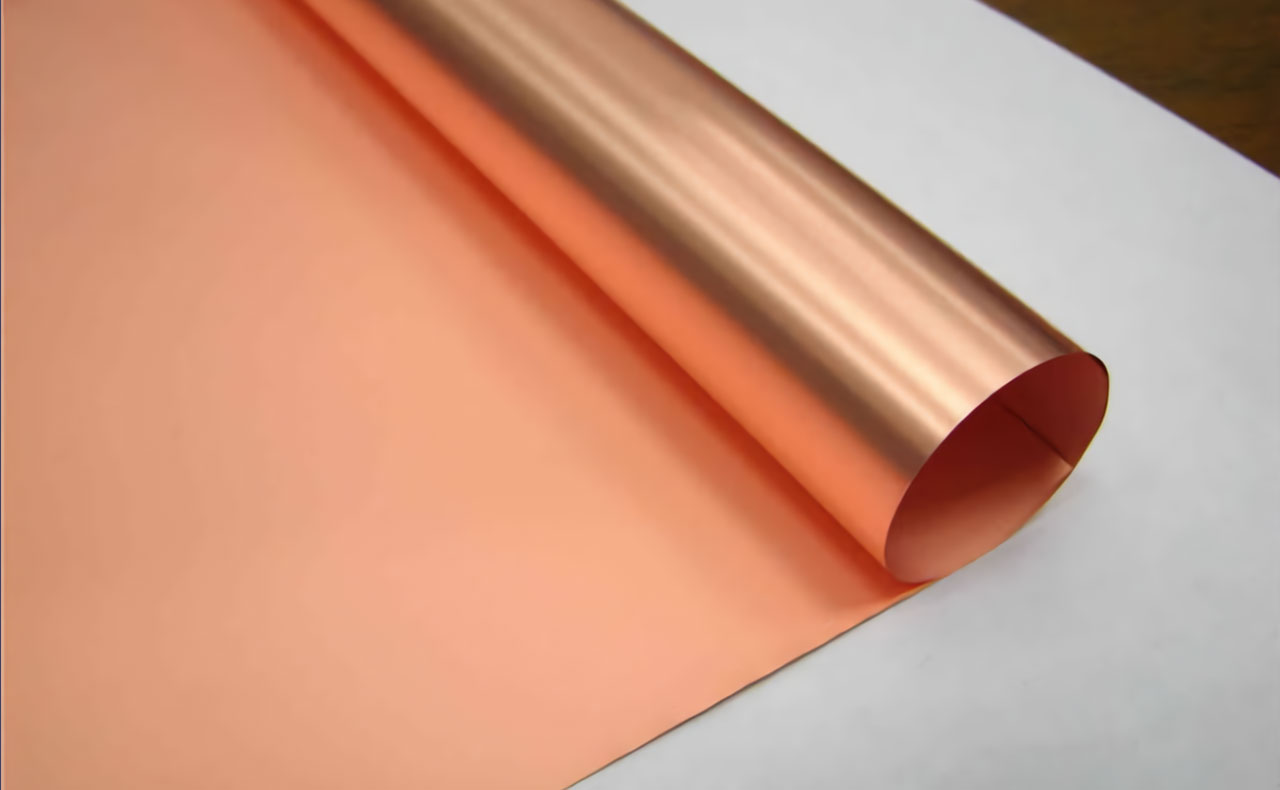

During the uncoiling process of the copper strip, surface tearing and deformation can often be seen, causing bonding defects. Bonding is easy to cause deformation, plasticity, and stamping performance of the copper tape for cables, which will seriously affect the qualification rate of the product.

1. Causes of bonding

The chemical composition of the surface of the copper strip, the temperature and time of the annealing process, and the compressive stress between the coils may all be the reasons for the bonding of the cable with the copper tape. The specific manifestations are as follows:

(1) Chemical composition of copper strip. The different microstructures of strips with different chemical compositions affect the speed of grain boundary migration on the contact surface, which in turn affects the interlayer bonding of copper strip coils.

(2) Surface cleanliness of copper strip. The volatile organic compounds remaining on the surface, such as emulsion, rolling oil, etc., have little effect on the bonding of the strip; the copper scraps and oxides attached to the surface of the strip will increase the local stress between the copper strip coils, and Strip bonding has a greater impact.

(3) Holding temperature and time. The higher the holding temperature and the longer the holding time, both are beneficial to the diffusion of atoms between the layers. Under the premise of ensuring that the copper strip can complete the recovery and recrystallization, the holding temperature and time should be controlled as strictly as possible.

(4) Cooling intensity. In the cooling stage, if the cooling rate is too large, it will cause the temperature difference between the outer layer and the middle layer to be too large, increase the compressive stress between the layers, and lead to adhesion. It is necessary to control the cooling strength reasonably.

(5) Width of copper strip coil ring. The greater the width of the copper strip coil, the worse the heat transfer effect of the outer layer and the middle layer, the left and right parts and the middle part, resulting in a larger temperature gradient.

(6) Curl tension of copper strip. Copper strip has high crimping tension and high compressive stress between layers, which will increase the tendency of strip bonding.

(7) Copper strip thickness difference and plate shape. Uneven copper strip thickness or poor plate shape will increase the local stress between layers.

(8) Surface roughness of copper strip. The smoother the surface of the copper strip, the tighter the layer rolls are attached, which is conducive to atomic diffusion and increases the bonding tendency of the copper strip.

2. Solution

(1) The copper strip is annealed in a low hydrogen atmosphere, and the holding temperature, holding time, cooling temperature, product temperature and cooling time are constantly adjusted. Using metallographic structure analysis, until the finished strip has completed the recovery and recrystallization process, and there is no abnormal phenomenon

(2) Before the copper strip enters the bell furnace, adjust the crimping tension to make the coiling tower good shape; and make the edges and surface of the strip free of burrs, copper chips and oxides.

(3) Adjust the plate width according to the surface roughness.