Fullway

Company profile

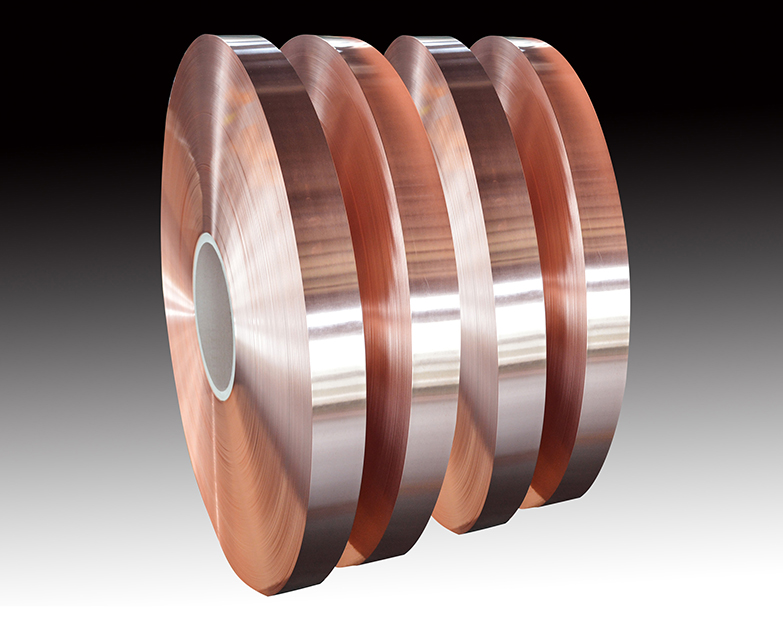

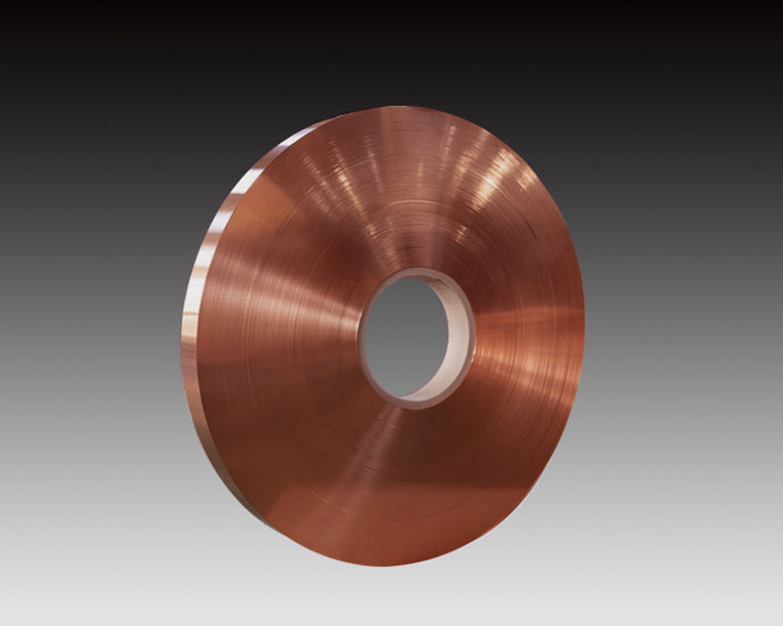

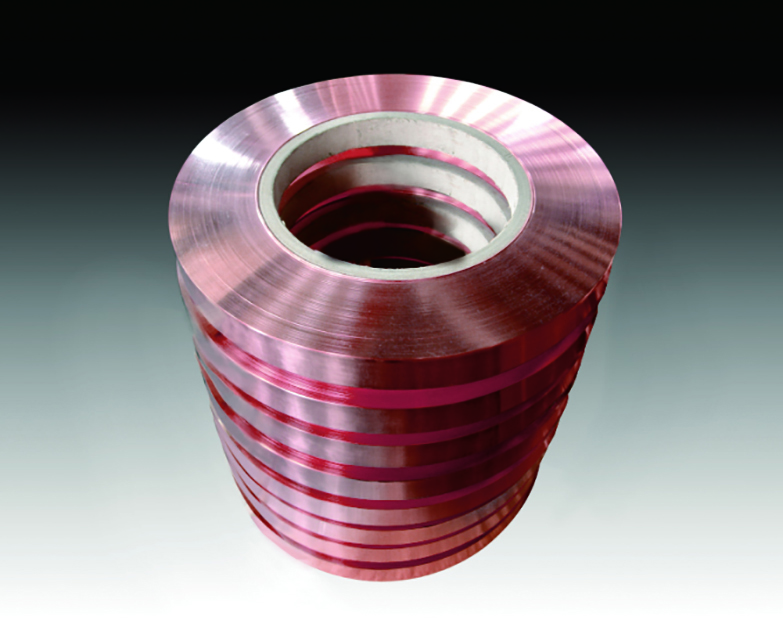

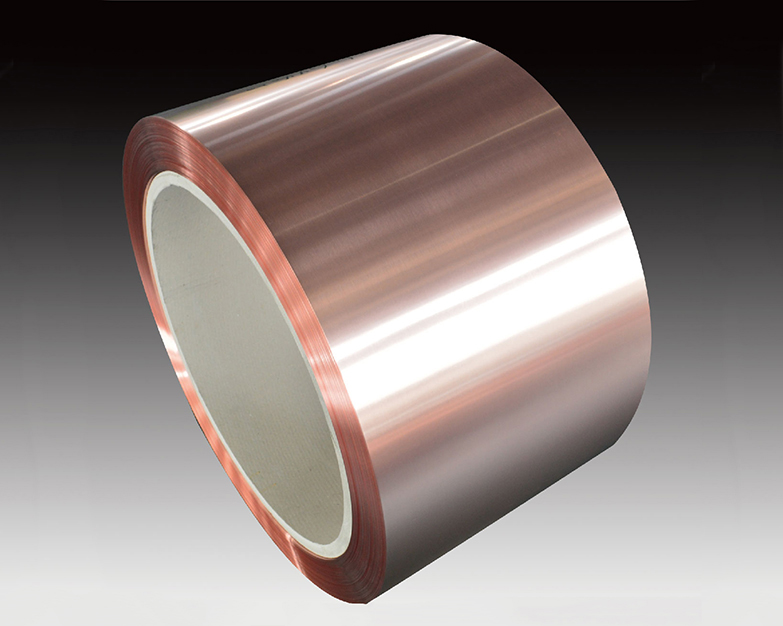

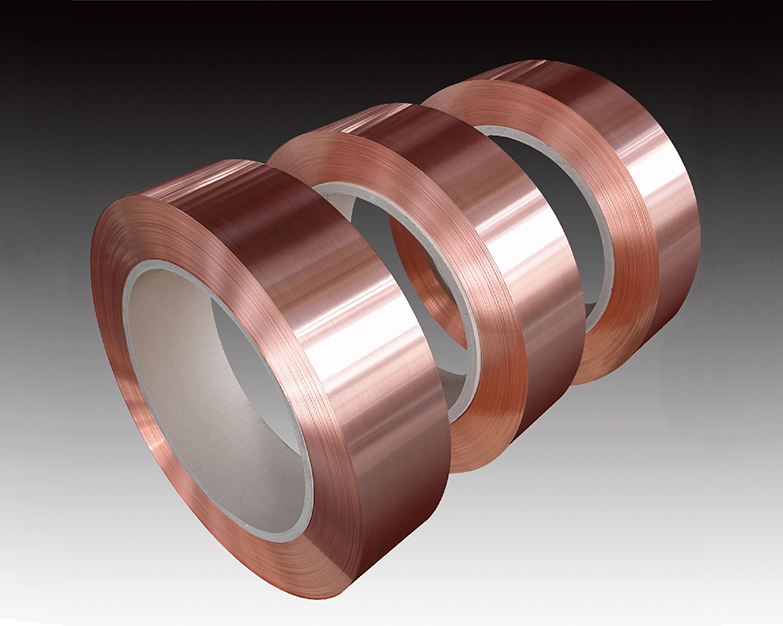

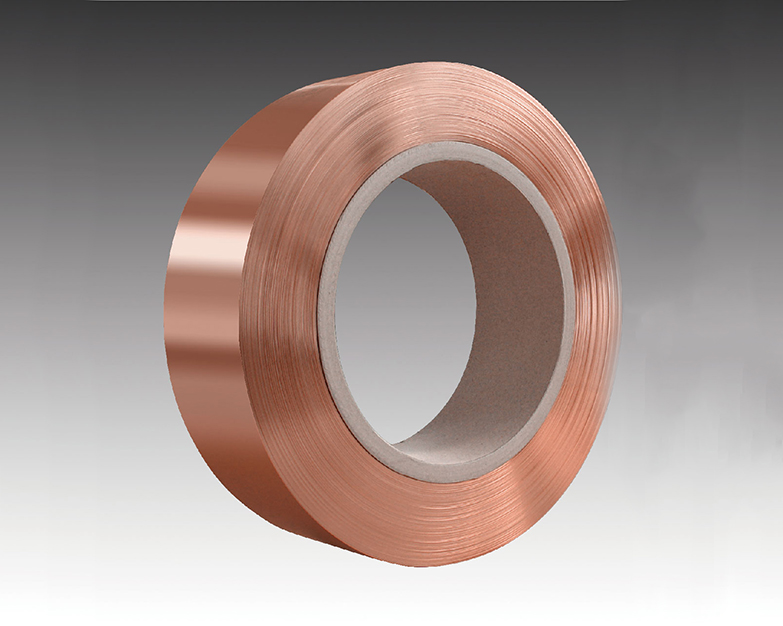

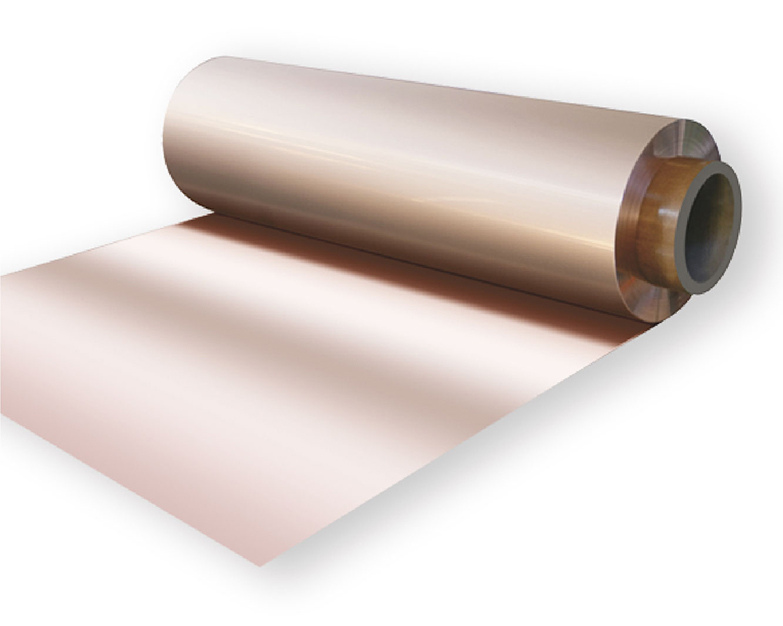

Since its establishment, the company has always adhered to market and brand strategy-oriented, faced the global market, and continuously expanded brand awareness. Its products are widely used in 5G, new energy, electronics, computers, communications, electric power, automobiles, railways, aerospace and other fields, and have been exported at home and abroad. Now it has become an important supplier of copper-based materials for many large enterprises and listed companies at home and abroad. It is an internationally renowned brand enterprise that Jiangsu Province focuses on cultivating and developing.

苏公网安备32050902100897

苏公网安备32050902100897